Mechanical assemblies

ANDRÉ LAURENT company is specialized in mechanical assemblies for fastening and binding. We manufacture tailor made assemblies in series starting from 100 pieces.

- Shock absorber assemblies

- Suspension pin assemblies

- Special machine assemblies

- Output shafts assemblies

- Gear mechanism

- Lifting mechanism

- Ring assemblies

- Gable assemblies…

Assembly process

- Kit assemblies

- Glued assemblies

- Welded assemblies

- Mounted assemblies

ANDRE LAURENT SAS, manufacturing of mechanical assemblies (starting from 200 pieces)

Materials used in assemblies

We manufacture these assemblies with different materials: steel, aluminum, bronze, copper alloys. We are able to manufacture stainless steel and titanium.

Find out more about materials.

Forged assemblies

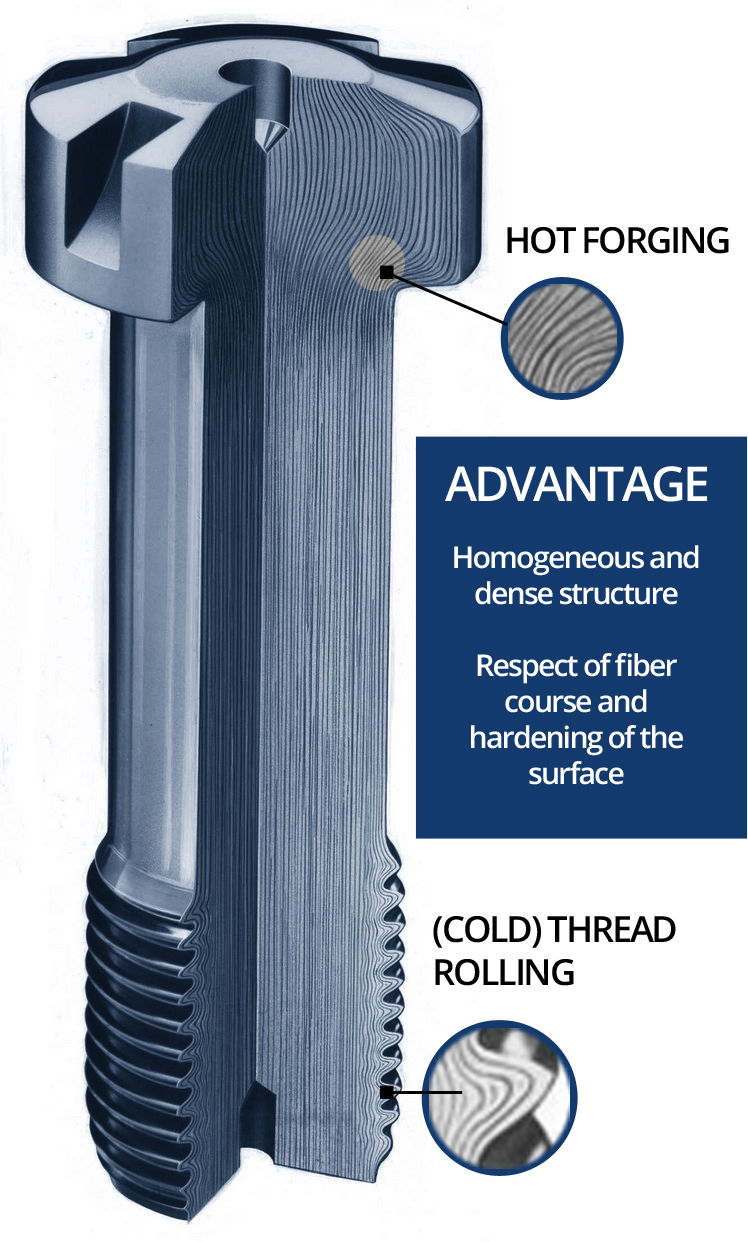

ANDRE LAURENT company uses hot forging process for economic reasons and to improve mechanical properties (continuous fibre course)

Thread rolling

Thanks to cold thread rolling, the component keeps a better surface rendering. Avec le filetage par roulage, la pièce conserve un meilleur état de la matière. The continuous fibre course allows improving mechanical properties of every component of the assembly (nuts, screws, rods) as well as a better fatigue strength.