INNOVATIVE PROJECTS

APPLICATIONS:

Aeronautics, Nuclear, Oil & Gas, Marine, Structural work, Turbines, Marine engine…

INNOVATION, ANDRE LAURENT’S DNA

Our involvement in major projects show the will to offer solutions that meet today’s clients challenges : “Mekinox” and “anti-loosening device”

Mekinox

Stainless fastening and mechanical assemblies

This innovative project aims to replace binding and mechanical elements using traditional steel by stainless steel.

Collaborative FUI project (Unique government fund)

Advantages

- Removing polluting treatment surface that do not comply with environmental standards (plating and hard chromium plating)

- Replacing traditional Steel by stainless steel material

- Decreasing maintenance cost through longer inspection time interval

Steel grade

- Notrogen alloyed stainless steel XD15NW and XD16N

- Stainless steel cementation CX13VDW

- Precipitation hardened stainless steel MLX17 and MLX19

Goals

- Finding solutions in stainless steel

- Optimizing machining processes

- Determining surface coating

ANTI-LOOSENING DEVICE

Anti-loosening device with reversed threading!

Process

The device is based on the addition of a thread or tapped element with a left-hand thread. This element will rely on the nut allowing it to ensure the main function of tightening.

The two parts are connected together by contact and friction, the rotation becomes impossible because of the inversion of the two pitches.

Two possibles ways :

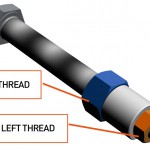

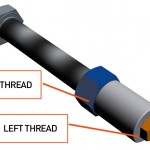

- External threading on the screw, the braking element is a left-handed pitch thread nut.

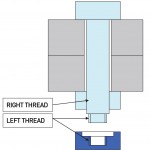

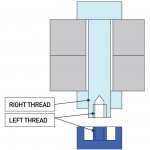

- Internal thread in the screw with a braking element as a screw with a left-hand pitch thread.

- Anti-loosening device with external reversed threading

- External threading on the screw with a breaking system like a left threaded nut

- Anti-loosening device with internal thread into the screw

- Tapping into the screw with a breaking system like a left threaded screw

Advantages

- No modification of the tightening characteristics

- Possibility to tighten, untighten or even reset the main nut without reducing the performance

- The function “anti-unscrewing” is kept even in the case of loss of tightening unlike the washer or device against unscrewing inserted between the nut and the tightened part.

- Same efficiency no matter what the hardness of the material is / with any hardness of material

- The bearing surface of the tightened part is not degraded / deteriorated

- Better performance facing transverse stress

- Easy to implement

- Possibility to add the device to existing mechanical assemblies without dismantling

- Multi materials system

- The protection of the extremity of the screw facilitates the maintenance operations